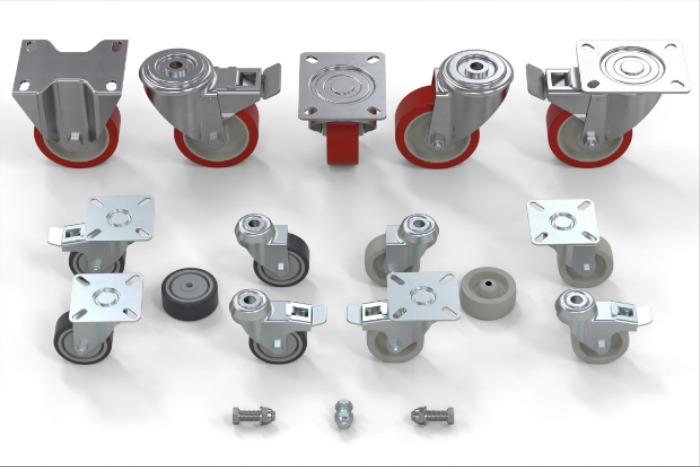

We have extended our range of castor wheels. Ideal for OEMs or end-users, this broad wheel range covers a variety of designs, materials, and sizes, for an array of industrial and commercial applications. With sizes now including a compact 50mm diameter, through to a 200mm wheel, castors also include brake and adjustable levelling options.

Castor wheel frames are available in either Stainless Steel, providing optimum resistance to corrosion and wear, or Zinc Plated Steel that provides good durability and rust resistance across many applications.

The wheels themselves are available in a range of materials that differ according to hardness. Softer castor wheels, like Rubber, are ideal when non-marking is required, or for a low-noise environment. The Polyurethane Resin wheel is suitable for a wide range of uses with a good balance of softness with durability and strength, while the Nylon wheel is the hardest wearing. Phenolic Resin wheels are also available, selected for their resistance to heat. These castors can be used in ovens or painting bays and can withstand temperatures up to 280°C, or cold temperatures down to -40°C.

The wheels are available in a variety of colours to suit the environment, including black, blue, white, and red. We also provides furniture castor wheels, ideal for office chairs and furniture, made from black Nylon with a Steel frame.

The expansion of the WDS range of castors now means that every design is available from a compact 50mm wheel diameter, suitable for smaller machines and low clearance heights, through to larger 200mm diameter wheels. Each type of castor wheel design also typically includes 80mm, 100mm, 125mm and 160mm diameter sizes.

Now, the expanded range has added new fixing kits for plate frame castors. Comprising all the bolts, nuts, and washers required to fix the frame to its host, the kits make specification and purchasing a faster and easier process. The fixing kits are available in packs of four or packs of 16.

About WDS Components Ltd

WDS Components is the home of standard parts and machine accessories. Established in 1952 ‘Woodside Die Sinking Company’ made jig and die parts to speed up production in tool rooms, WDS Components has grown from humble beginnings to become a leading European manufacturer and global distributor of high quality durable parts at competitive prices. We supply components, standard parts and machine accessories to original equipment manufacturers, maintenance engineers, small businesses and individuals all over the world. Over 98% of our range is available from stock and can be shipped the same day from our global distribution centre in the UK, using best in class worldwide logistics companies.

We provide unrivalled choice and unequalled availability.

WDS Components are proud to support some of the most prestigious engineering companies and brands in the world, who all trust WDS Components to service their needs.

We are committed to engineering excellence and continuous improvement. Our team of in-house engineers has expertise spanning several decades and is a blend of highly experienced and new generation graduate engineers who focus on the latest developments in design and manufacturing technology.

Our entire range of products is available to purchase on our website WDS COMPONENTS.COM where designers and manufacturers alike can download 3D models of all components in the widest range of formats available.

WDS Components provide solutions for customers who require a wide and growing range of high quality, competitively priced products, coupled with incredible product availability and same day despatch, backed up by easily accessible technical support.

Further Information:

Website: WDS COMPONENTS.COM

Email: Sales@wdscomponents.com